Rubber tubingya sha bamban da sauran bututun saboda abin da ke cikin roba, wanda shi ne elastomer wanda ke da ƙarfi da ƙarfi kuma yana iya miƙewa da nakasa ba tare da lalacewa ta dindindin ba.Wannan ya samo asali ne saboda sassauƙarsa, juriya na hawaye, juriya, da kwanciyar hankali na thermal.

Ana samar da bututun roba ta amfani da ɗayan matakai guda biyu.Hanya ta farko ita ce amfani da maɗaukaki, inda ake naɗe ɗigon roba a kusa da bututu kuma ana dumama.Hanya na biyu shine extrusion, inda ake tilasta roba ta hanyar mutuwa.

YayaRubber TubingAn yi?

Tsarin Mandrel

Roba Roll

Ana isar da robar da ake amfani da shi don kera bututun roba ta hanyar amfani da tsarin mandrel don samarwa a cikin naɗaɗɗen tube na roba.An ƙaddara kauri daga cikin ganuwar tubing ta hanyar kauri daga cikin zanen gado.An ƙaddara launi na tubing ta launi na nadi.Ko da yake launi ba lallai ba ne, ana amfani da shi azaman hanyar yanke shawarar rarrabawa da amfani na ƙarshe na bututun roba.

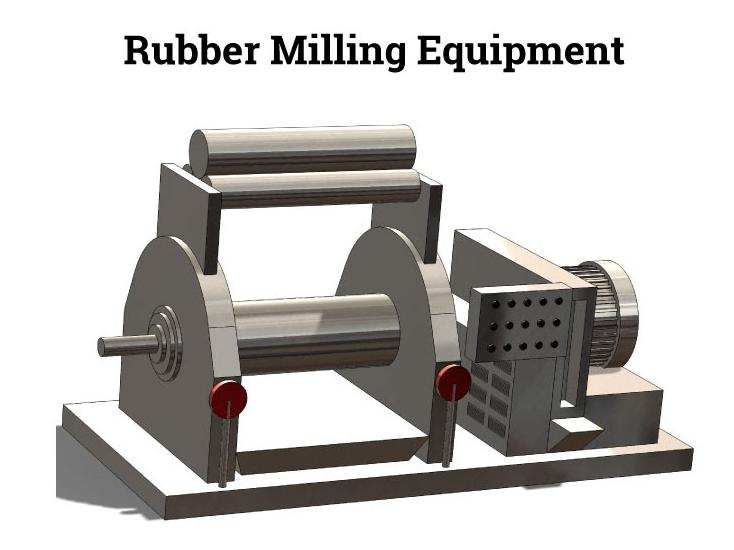

Milling

Don yin robar ya zama mai jujjuyawa don aikin samarwa, ana gudanar da shi ta cikin injin niƙa da ke dumama igiyoyin roba don yin laushi da santsi don tabbatar da cewa yana da nau'i mai ma'ana.

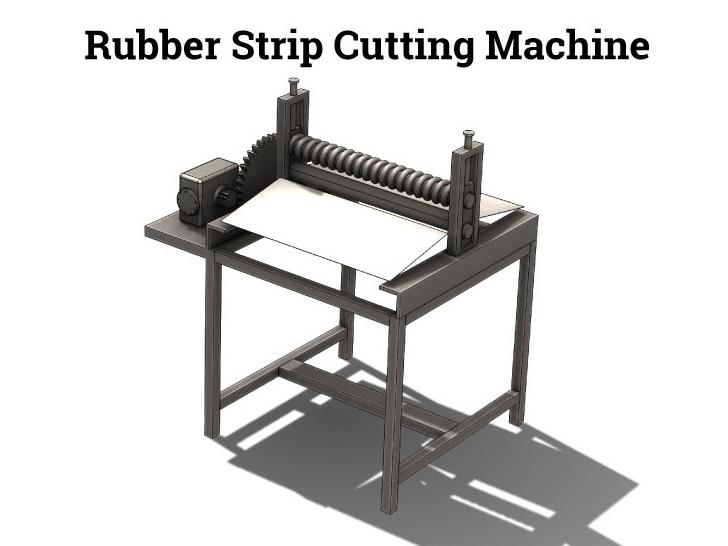

Yanke

Robar mai laushi da mai jujjuyawa ana matsar da ita zuwa injin yankan da ke yanke shi cikin filaye daidai da faɗi don dacewa da faɗi da kauri na girman bututun roba da za a yi.

Mandrel

Ana aika sassan da aka ƙirƙira a cikin yankan zuwa ga mandrel.Kafin a nannade tsiri a kan mandrel, ana shafa man da man zaitun.Diamita na mandrel shine ainihin ma'auni a matsayin ɗigon bututun roba.Yayin da mandrel ya juya, an nannade ratsan roba a kusa da shi a daidai da taki.

Ana iya maimaita tsarin nannade don isa kauri da ake so na bututun roba.

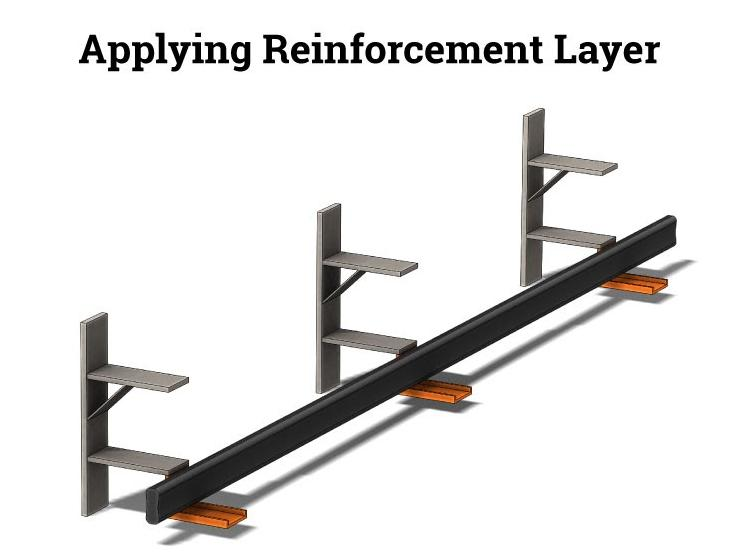

Ƙarfafa Layer

Bayan bututun ya kai daidai da kauri, an ƙara wani Layer na ƙarfafawa wanda aka yi da wani abu mai ƙarfi mai ƙarfi wanda aka rufe da roba.Zaɓin zaɓi na Layer an ƙaddara ta yawan matsa lamba da bututun roba zai iya jurewa.A wasu lokuta, don ƙarin ƙarfi, ƙirar ƙarfafawa na iya ƙara waya.

Layer Karshe

Layer na ƙarshe na tube roba shine suturar sa ta waje.

Taɓa

Da zarar an yi amfani da duk nau'i-nau'i daban-daban na raƙuman roba, cikakken tsayin tubing ɗin da aka kammala yana nannade cikin rigar nailan.Tef ɗin zai ragu kuma ya danne kayan tare.Sakamakon faifan tef ɗin shine ƙarewar rubutu akan diamita na waje (OD) na tubing wanda ya zama kadara da fa'ida ga aikace-aikacen da za a yi amfani da bututun.

Vulcanization

Ana sanya tubing akan mandrel a cikin autoclave don tsarin ɓarna wanda ke warkar da roba, wanda ya sa ya zama na roba.Da zarar an gama vulcanization, ana cire tef ɗin nailan da ya shuɗe.

Cire daga Mandrel

Ɗayan ƙarshen bututu an rufe shi sosai don haifar da matsa lamba.Ana yin rami a cikin bututun don zubar da ruwa a ciki don raba bututun roba daga madaidaicin.Ana sauke bututun roba cikin sauƙi daga maɗaurin, ana gyara ƙarshensa, kuma an yanke shi zuwa tsayin da ake so.

Hanyar Extrusion

Tsarin extrusion ya ƙunshi tilasta roba ta hanyar mutuwa mai siffar diski.Bututun roba da tsarin extrusion ya yi yana amfani da fili mai laushi mara lalacewa.Sassan da aka samar ta amfani da wannan hanyar suna da taushi kuma masu jujjuyawa, waɗanda suke ɓarna bayan aikin extrusion.

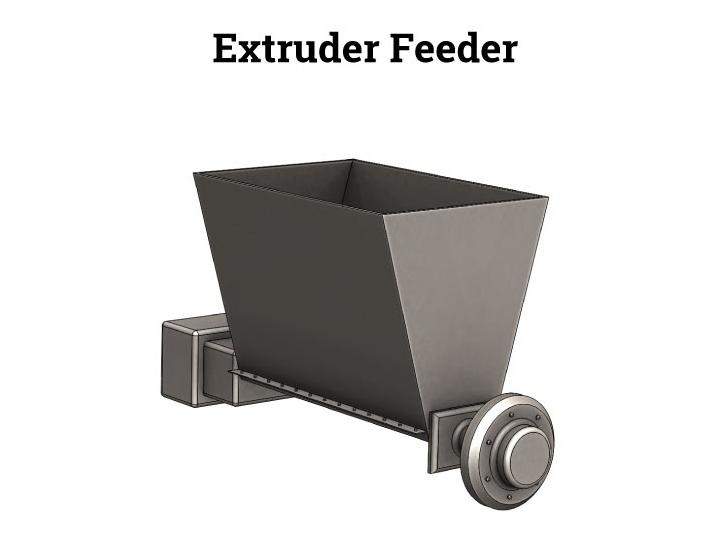

Ciyarwa

Tsarin extrusion yana farawa ta hanyar ciyar da fili na roba a cikin extruder.

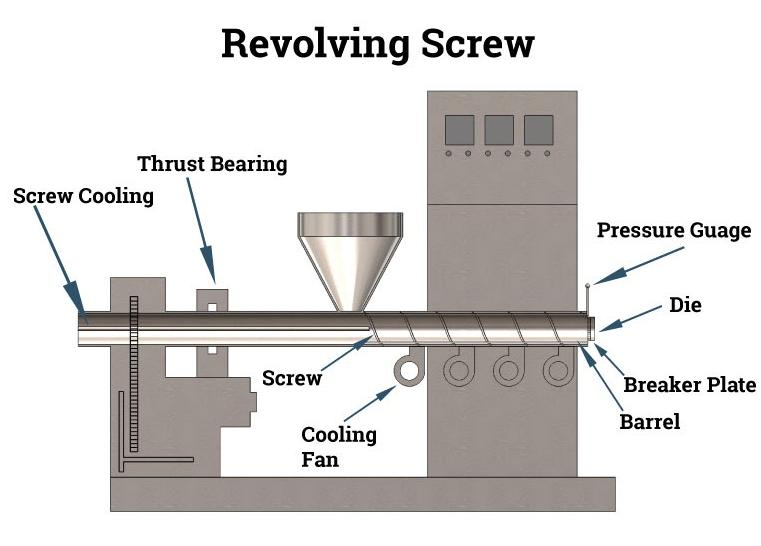

Juyawa Screw

Ginin roba a hankali yana barin mai ciyarwa kuma ana ciyar da shi zuwa dunƙule wanda ke matsar da shi zuwa ga mutuwa.

Rubber Tubing mutu

Yayin da danyen kayan roba ke motsawa tare da dunƙule, an tilasta shi ta hanyar mutuwa a daidai gwargwadon diamita da kauri don bututu.Yayin da roba ke matsawa kusa da mutuwa, ana samun karuwar zafin jiki da matsa lamba, wanda ke haifar da abin da ke fitar da kayan ya kumbura dangane da nau'in fili da taurin.

Vulcanization

Tun da roban da ake amfani da shi wajen fitar da shi ba a fallasa shi ba, dole ne a sha wani nau'i na vulcanization da zarar an yi ta hanyar fitar da shi.Ko da yake jiyya da sulfur shine ainihin hanyar vulcanization, wasu nau'ikan an haɓaka su ta hanyar masana'anta na zamani, waɗanda suka haɗa da magungunan microware, wankan gishiri, ko wasu nau'ikan dumama iri-iri.Tsarin ya zama dole don raguwa da taurare samfurin da aka gama.

Za'a iya ganin tsarin ɓarna ko warkarwa a cikin zanen da ke ƙasa.

Lokacin aikawa: Agusta-25-2022